Double-wall paper cup machines play an important role in the packaging industry, and their prices are affected by a variety of factors. A deep understanding of these influencing factors is of extremely crucial significance for manufacturers, purchasers, and related practitioners in terms of equipment selection, cost control, and market competition. It helps them make more informed and reasonable decisions to adapt to the constantly changing market demands and industry development trends.

Brand Factors

Brand Awareness: Well-known brands usually enjoy high reputation and recognition in the market. Their products have generally undergone long-term market tests, and their quality and performance are relatively more guaranteed. Therefore, their prices tend to be higher. For example, some leading brands in the industry have made significant investments in research and development, production processes, and quality control. The price of their double-wall paper cup machines may be much higher than that of ordinary brands.

Brand Reputation: A good brand reputation reflects consumers' satisfaction and trust in the brand's products. If a brand's double-wall paper cup machines receive numerous positive reviews in the market, with users reporting that the equipment is stable, has high production efficiency, and offers good after-sales service, etc., then the price of the brand's products will also be positively affected. Consumers are often willing to pay a higher price for it because they believe that such a brand can bring a better user experience and long-term value.

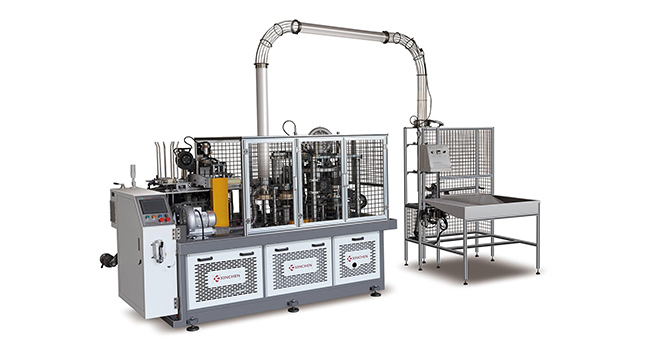

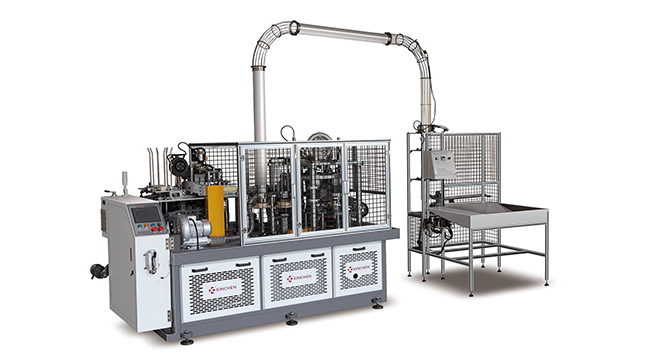

Technical Parameters and Performance

Production Speed: Production speed is one of the important indicators for measuring the efficiency of double-wall paper cup machines. Generally speaking, the faster the production speed of a machine, the higher its price. For example, compared with a machine that can produce 50 - 80 paper cups per minute, a machine that can produce 100 - 150 paper cups per minute usually has a higher price because it can produce more paper cups within a unit time, meeting the needs of large-scale production and thus bringing higher economic benefits to enterprises.

Degree of Automation: Fully automatic double-wall paper cup machines, due to their higher degree of automation, can reduce manual operations, improve production efficiency and the stability of product quality. Their prices are often higher than those of semi-automatic or manual machines. Fully automatic machines are equipped with advanced control systems, sensors, and automation devices, which can realize a series of operations such as automatic paper feeding, paper cup forming, and bottom sealing. The application of these advanced technologies and devices increases the cost of the equipment, thereby affecting the price.

Adaptability to Paper Cup Specifications: Double-wall paper cup machines that can adapt to the production of various paper cup specifications have relatively higher prices. Such machines usually have adjustable molds or devices that can easily switch to the production of paper cups of different sizes, providing enterprises with greater production flexibility to meet the order requirements of different customers. However, this also increases the complexity and manufacturing cost of the equipment, leading to a price increase.

Equipment Precision: High-precision double-wall paper cup machines can meet higher quality standards in the processes of paper cup forming, bottom sealing, and bonding, producing paper cups with better quality, such as better sealing and more regular appearance. To achieve high-precision production, such machines have higher requirements in terms of mechanical structure design, machining precision of parts, and precision of the control system, thereby increasing the manufacturing cost of the equipment and correspondingly increasing the price.

Equipment Configuration

Quality of Core Components: The quality of core components of double-wall paper cup machines, such as motors, reducers, control systems, and ultrasonic generators, directly affects the performance and service life of the equipment. Machines using high-quality imported or well-known brand core components, although having higher costs, can ensure the stable operation and efficient production of the equipment. Therefore, their prices will be more expensive than those of machines using ordinary components.

Auxiliary Devices and Functions: Some double-wall paper cup machines are equipped with additional auxiliary devices and functions, such as automatic counting, fault alarm, remote monitoring, and waste recycling systems. These devices and functions can improve the convenience of production management and the environmental protection of the production process, but they will also increase the cost and price of the equipment. For example, for a machine with remote monitoring function, enterprises can remotely monitor the running state of the equipment in real time through the network, discover and solve problems in a timely manner, and improve production efficiency. However, the price of such a machine will be higher than that of an ordinary machine by a certain proportion.

Production Scale and Cost

Large-Scale Production: For manufacturers of double-wall paper cup machines engaged in large-scale production, since the production quantity is large, they can reduce the unit production cost by means of large-scale procurement of raw materials, optimization of production processes, and improvement of production efficiency, etc., and thus can offer more competitive prices to a certain extent. On the contrary, manufacturers of small-batch production cannot enjoy the cost advantages brought by economies of scale, and their product prices may be relatively high.

Production Cost: The production cost of manufacturers is also an important factor affecting the price of double-wall paper cup machines. Production costs include raw material costs, labor costs, research and development costs, management costs, and marketing costs. If the price of raw materials rises, labor wages increase, research and development investment increases, or marketing expenses expand, etc., all will lead to an increase in production cost, which in turn will push up the product price.

After-Sales Service

Service Quality: High-quality after-sales service is crucial for the long-term stable operation of double-wall paper cup machines. Manufacturers that provide comprehensive after-sales service, such as timely technical support, rapid repair response, and sufficient supply of spare parts, can make users feel more at ease during the use process and reduce production losses caused by equipment failures. Therefore, the product prices of such manufacturers may include a certain amount of after-sales service fees and are relatively high.

Service Content and Duration: The service content and duration provided by different manufacturers also vary. Some manufacturers may offer a longer warranty period, a more comprehensive warranty scope, and free equipment maintenance training, etc. These additional services will increase the cost of the manufacturers and be reflected in the product price.

Nov 20,2024

Nov 20,2024