The paper cup packing machine is a crucial part in the production and sales chain of paper cups. It affects multiple aspects such as packaging efficiency, product presentation, and hygiene conditions. An in-depth exploration of it includes aspects like functional principles, types and features, selection points, and maintenance matters. This can help relevant practitioners make accurate choices, use and maintain the equipment properly, and thus achieve the dual goals of efficient production and high-quality packaging in a highly competitive market environment.

I. Basic Functions and Working Principles

A paper cup packing machine is designed to efficiently package paper cups. It typically operates by first gathering a set number of paper cups, which could be a specific quantity like 50 or 100 cups, depending on the preset packaging requirements. The cups are then carefully arranged and inserted into a packaging material, often a plastic film or a paper sleeve. The machine uses a combination of mechanical arms, conveyors, and sealing mechanisms to ensure the cups are properly placed and the packaging is securely sealed. For example, the mechanical arms may pick up the cups from a production line and transfer them in an orderly manner onto the conveyor leading to the packaging area. The sealing mechanism applies heat or pressure to close the packaging, creating a neat and protective enclosure for the paper cups.

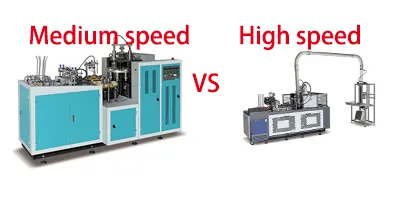

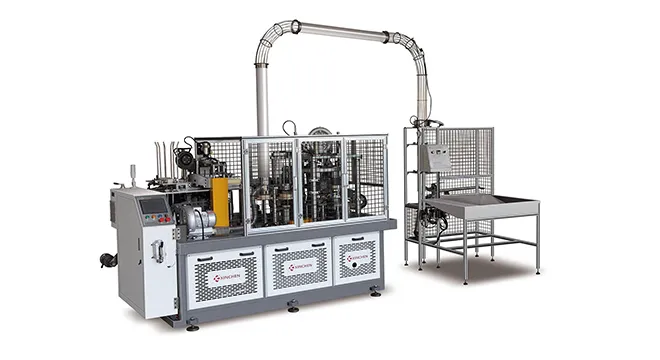

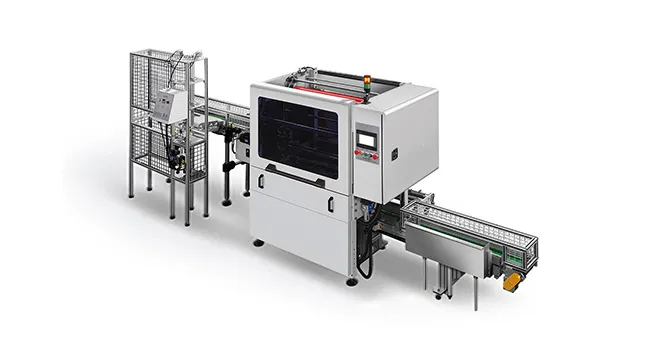

II. Types of Paper Cup Packing Machines

There are several types of paper cup packing machines available in the market. One common type is the horizontal packing machine. This machine arranges the paper cups horizontally and then wraps them with the packaging material. It is suitable for cups of various sizes and can handle relatively high production volumes. Another type is the vertical packing machine, which stacks the paper cups vertically before packaging. Vertical packing machines are often preferred for their compact design and ability to save space on the production floor. Additionally, there are fully automatic and semi-automatic paper cup packing machines. Fully automatic machines require minimal human intervention and can continuously operate, adjusting to different packaging specifications automatically. Semi-automatic machines, on the other hand, may need an operator to perform certain tasks such as loading the cups onto the machine or initiating the packaging process, but they are generally more cost-effective and suitable for smaller-scale production operations.

III. Key Features and Advantages

1.High Efficiency: Paper cup packing machines can significantly increase the packaging speed compared to manual packaging. They can process a large number of cups in a short time, thereby improving overall production efficiency and reducing labor costs. For instance, a modern fully automatic paper cup packing machine can package thousands of cups per hour, allowing manufacturers to meet large orders in a timely manner.

2.Precision Packaging: These machines ensure accurate and consistent packaging. The cups are precisely arranged and packaged, minimizing the risk of damage during transportation and storage. The sealed packaging also helps maintain the cleanliness and integrity of the paper cups, making them more appealing to consumers.

Versatility: Many paper cup packing machines are designed to be versatile. They can handle different sizes and shapes of paper cups, as well as various types of packaging materials. This flexibility enables manufacturers to adapt to different market demands and produce a wide range of packaged paper cup products.

By automating the packaging process, the machines reduce the need for human contact with the paper cups, thereby improving hygiene standards. This is especially important in the food and beverage industry, where strict hygiene regulations must be adhered to.

IV. Considerations for Selection

Production Capacity: When choosing a paper cup packing machine, it is essential to consider the required production capacity. Manufacturers should assess their current and future production needs to select a machine that can handle the expected volume of paper cups. If the production volume is likely to increase in the future, it may be advisable to invest in a machine with a higher capacity or one that can be easily upgraded.

Cup Size and Type Compatibility: The machine should be compatible with the specific sizes and types of paper cups being produced. Different machines have different limitations in terms of the cup diameter, height, and shape they can handle. It is crucial to ensure that the selected machine can accommodate the full range of cup products to avoid the need for additional equipment or manual packaging for certain cup variants.

Packaging Material Compatibility: Consider the type of packaging material to be used. Some machines are optimized for plastic film packaging, while others work better with paper sleeves or other materials. Ensure that the machine can effectively seal and handle the chosen packaging material to achieve the desired packaging quality.

: Look for a machine that is easy to maintain and has reliable after-sales service. Regular maintenance is necessary to keep the machine running smoothly and minimize downtime. A good after-sales service provider can offer technical support, spare parts, and assistance in case of any machine malfunctions or breakdowns.

V. Maintenance and Troubleshooting

Regular Cleaning: To ensure the proper functioning of the paper cup packing machine, regular cleaning is essential. This includes cleaning the conveyor belts, mechanical arms, and packaging area to remove any paper debris, dust, or adhesive residue. A clean machine operates more efficiently and reduces the risk of jams or malfunctions.

Lubrication: The moving parts of the machine, such as gears, shafts, and bearings, need to be regularly lubricated. This helps reduce friction and wear, prolonging the life of the machine. Use the appropriate lubricants recommended by the manufacturer and follow the proper lubrication schedule.

Troubleshooting Common Issues: Some common issues that may arise with paper cup packing machines include cup jams, improper sealing, and mechanical failures. If a cup jam occurs, first stop the machine and carefully remove the jammed cups, checking for any obstructions or misalignments in the cup path. For improper sealing, check the temperature and pressure settings of the sealing mechanism and ensure that the packaging material is properly loaded. In case of mechanical failures, refer to the machine's manual for troubleshooting steps or contact the manufacturer's technical support team.

By understanding the various aspects of paper cup packing machines, manufacturers and users can make informed decisions about their selection, operation, and maintenance, ensuring efficient and reliable paper cup packaging operations.

The paper cup packing machine is a crucial part in the production and sales chain of paper cups. It affects multiple aspects such as packaging efficiency, product presentation, and hygiene conditions. An in-depth exploration of it includes aspects like functional principles, types and features, selection points, and maintenance matters. This can help relevant practitioners make accurate choices, use and maintain the equipment properly, and thus achieve the dual goals of efficient production and high-quality packaging in a highly competitive market environment.

Nov 21,2024

Nov 21,2024