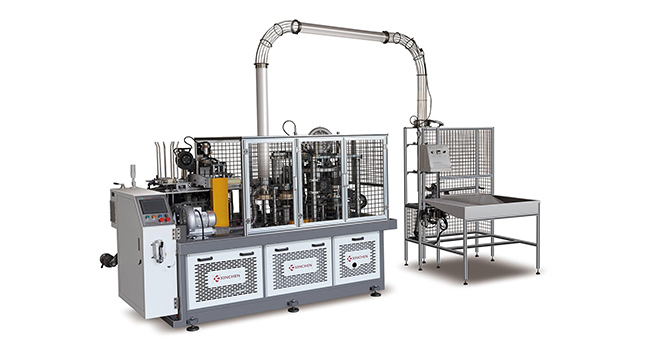

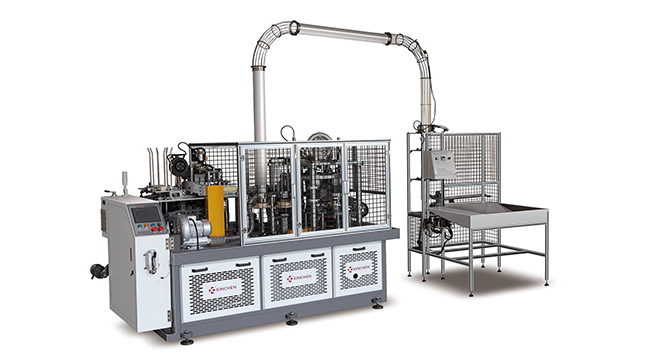

In the fast - paced world of modern packaging, paper cup making machines play a pivotal role. These ingenious devices have transformed the way we produce and consume paper cups, which have become an essential part of our daily lives, whether it's for our morning coffee, a refreshing cold drink, or at events and gatherings.

The Intricate Working Process

Paper Feeding

The journey of a paper cup begins with the paper feeding stage. High - quality paper reels, often made from food - grade paperboard, are loaded onto the machine. The paperboard is carefully designed to be sturdy enough to hold liquid yet lightweight for easy handling. The paper cup forming machine then unwinds the paper in a controlled manner, ensuring a steady and continuous supply for the subsequent processes.

Cup Forming

Once the paper is fed, the cup - forming process commences. The paper is first cut into precise circular shapes, which will form the body of the cup. These circular pieces are then shaped into a cup - like structure. This is achieved through a combination of mechanical presses and molds. The paper is pressed and shaped around the mold, which gives it the characteristic cup shape. The edges of the paper are carefully sealed together, either through heat - sealing or using food - grade adhesives. This ensures that the cup is leak - proof and can safely hold liquids.

Bottom Attachment

After the cup body is formed, the next crucial step is attaching the bottom. A separate circular piece of paperboard, which has been pre - cut and prepared, is attached to the open end of the cup body. This attachment is done with great precision. The bottom is either glued or heat - sealed to the cup body, creating a seamless and secure connection. The strength of this connection is vital as it determines the cup's ability to hold liquid without any leakage.

Finishing Touches

Some advanced paper cup making machines also add finishing touches. This can include applying a special coating to the inner surface of the cup. This coating is usually made of a food - safe material, such as polyethylene, which not only enhances the cup's ability to hold liquid but also prevents the paper from getting soggy. Additionally, the machines can be equipped to print logos, designs, or marketing messages on the outer surface of the cup. This can be done through various printing techniques, such as flexography or digital printing, allowing businesses to promote their brand or event on the cups.

Technological Features and Innovations

Automation

Modern paper cup making machines are highly automated. They are equipped with sensors and control systems that monitor and regulate the entire production process. For example, sensors can detect if there is any misalignment in the paper feeding or if the cup - forming process is not going as planned. The control system can then automatically adjust the machine settings to correct any issues, ensuring a smooth and continuous production flow. This automation not only increases production efficiency but also reduces the need for manual intervention, minimizing the risk of human error.

High - Speed Production

These machines are designed for high - speed production. Depending on the model and its capabilities, a paper cup making machine can produce hundreds of cups per minute. This high - speed production is crucial for meeting the demands of large - scale food and beverage industries, as well as for events and catering services. The ability to produce a large number of cups in a short time helps businesses keep up with consumer demand and maintain their operations efficiently.

Customization Options

Paper cup making machines offer a wide range of customization options. They can be adjusted to produce cups of different sizes, from small espresso cups to large tumblers. The machines can also accommodate various paperboard thicknesses and types, allowing for the production of cups with different levels of durability. Moreover, as mentioned earlier, the printing capabilities of these machines enable the creation of unique and branded cups, which is highly valued by businesses looking to make a mark in the market.

Advantages of Paper Cup Making Machines

Cost - Efficiency

In the long run, investing in a paper cup making machine can be highly cost - effective. While the initial purchase of the machine may require a significant capital outlay, the savings in the production process are substantial. Producing cups in - house reduces the need to purchase cups from external suppliers, eliminating the associated costs of transportation and middle - man markups. Additionally, the high - speed production capabilities of the machines mean that the cost per cup is significantly reduced as the volume of production increases.

Hygiene and Safety

Paper cup making machines ensure a high level of hygiene and safety in the cup - making process. Since the production is automated and takes place in a controlled environment, the risk of contamination is minimized. The use of food - grade materials and proper sealing techniques during the cup - forming process ensures that the cups are safe for holding food and beverages. This is of utmost importance, especially in the food and beverage industry, where strict hygiene and safety standards must be adhered to.

Environmental Friendliness

Paper cups are a more environmentally friendly option compared to some other types of disposable cups, such as plastic. Paper is a renewable resource, and many paper cup making machines can use recycled paperboard as a raw material. Additionally, paper cups are biodegradable, which means they break down naturally over time, reducing the amount of waste that ends up in landfills. By using paper cup making machines, businesses can contribute to a more sustainable future.

Applications in Different Industries

Food and Beverage

The food and beverage industry is the primary user of paper cup making machines. Coffee shops, cafes, and restaurants rely on these machines to produce cups for their hot and cold beverages. Fast - food chains also use paper cups for serving drinks with their meals. The ability to customize the cups with the brand's logo and colors helps these businesses enhance their brand visibility and customer experience.

Events and Catering

For events such as weddings, parties, and corporate functions, paper cups are a convenient and cost - effective option for serving drinks. Catering companies often use paper cup making machines to produce cups in large quantities, ensuring they have enough cups for their guests. The customization options of these machines allow event organizers to create cups that match the theme of the event, adding a personal touch.

Retail

In the retail industry, paper cups are used for sampling products, such as food samples in supermarkets or perfume samples in department stores. Retailers can use paper cup making machines to produce cups with their store logo, which not only serves as a practical container but also as a marketing tool.

In conclusion

Paper cup making machines are a remarkable piece of technology that has revolutionized the paper cup production process. Their efficiency, technological features, and wide range of applications make them an essential asset in various industries. As technology continues to advance, we can expect even more innovative features and improvements in these machines, further enhancing their role in the world of packaging.

Feb 20,2025

Feb 20,2025