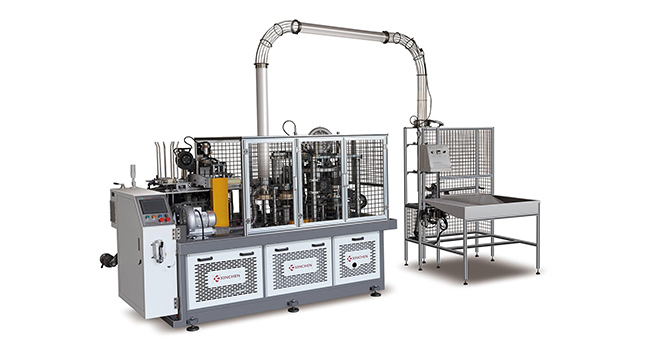

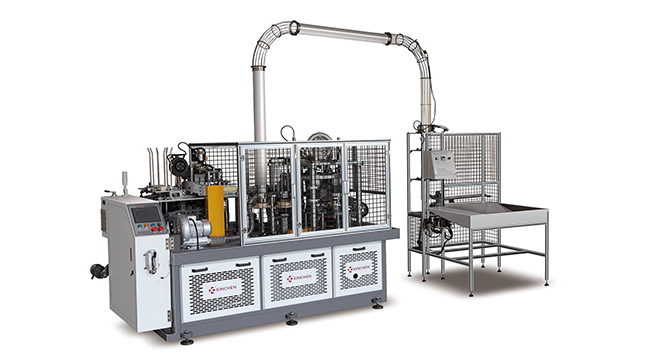

A Paper Cup Machine is a specialized piece of equipment used for manufacturing disposable paper cups. These machines are essential in industries that require large volumes of single-use cups, such as for beverages, food packaging, and medical applications. In this article, we will delve into how paper cup machines work and why they are vital to modern production processes.

How Does a Paper Cup Machine Work?

A paper cup machine automates the entire process of making paper cups, from shaping the cup to the final sealing. The process starts with a roll of paper that is fed into the machine. The machine then cuts the paper into circular pieces, which are formed into the shape of a cup using molds and pressure. These cups are then sealed using a combination of heat and pressure, ensuring that the cup holds its form and can withstand liquids without leaking. The machine also adds a layer of wax or plastic coating to make the cups waterproof.

Once the cups are formed, they are stacked and ejected for packaging, making the process highly efficient. High-speed paper cup machines can produce thousands of cups per hour, allowing manufacturers to meet the high demand for disposable cups in various sectors.

Types of Paper Cup Machines

There are mainly two types of paper cup machines: fully automatic and semi-automatic. Fully automatic machines are capable of performing all steps of the production process with minimal human intervention, including paper feeding, shaping, sealing, and stacking. These machines are ideal for large-scale production and can handle a variety of cup sizes and designs. On the other hand, semi-automatic machines require some manual input and are typically used for smaller production runs.

Additionally, there are machines designed to produce specific types of cups, such as double-wall paper cups for hot beverages or paper cups with special coatings for better insulation.

Why Are Paper Cup Machines Important?

1. Efficiency: Paper cup machines significantly reduce labor costs and increase production speed. The automation of the cup-making process allows manufacturers to meet high demand without sacrificing quality.

2. Customization: Modern paper cup machines are highly customizable. Manufacturers can design cups with unique prints, logos, and colors to meet branding and marketing needs.

3. Environmental Impact: Paper cups are a popular alternative to plastic cups due to their biodegradable nature. The use of paper cup machines contributes to the reduction of plastic waste, aligning with the growing demand for eco-friendly solutions.

4. Versatility: These machines can produce cups in various sizes and designs, catering to different industries. From coffee cups to soup cups, paper cup machines can adapt to a wide range of products, ensuring they meet the specific requirements of various markets.

The Future of Paper Cup Machines

As the demand for eco-friendly products rises, the paper cup industry is likely to continue evolving. New technologies are being developed to improve efficiency, reduce waste, and make the production process even more sustainable. For example, some newer machines use advanced sensors to minimize paper waste and increase the accuracy of cup shaping.

In conclusion, paper cup machines play a crucial role in the efficient and sustainable production of disposable cups. By understanding how these machines operate and their impact on industries worldwide, we can better appreciate the convenience of the paper cups we use daily. With advancements on the horizon, the future of paper cup manufacturing looks bright, offering solutions that balance efficiency with environmental responsibility.

Feb 14,2025

Feb 14,2025