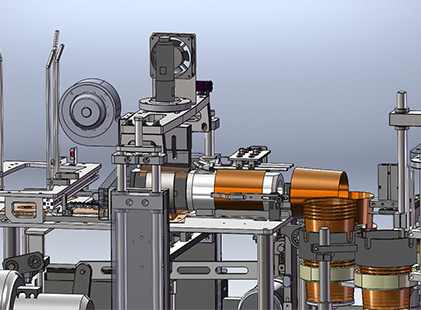

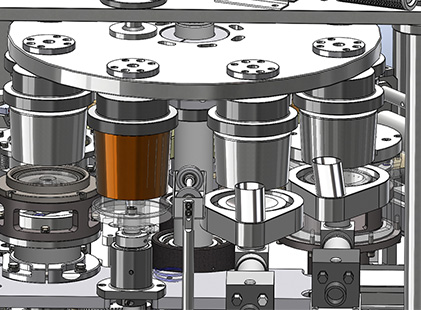

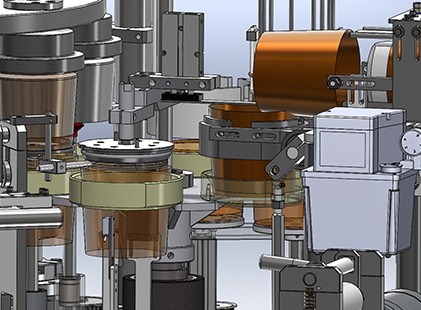

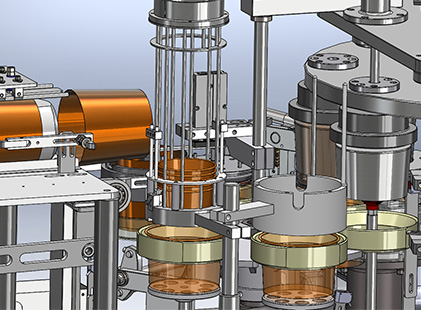

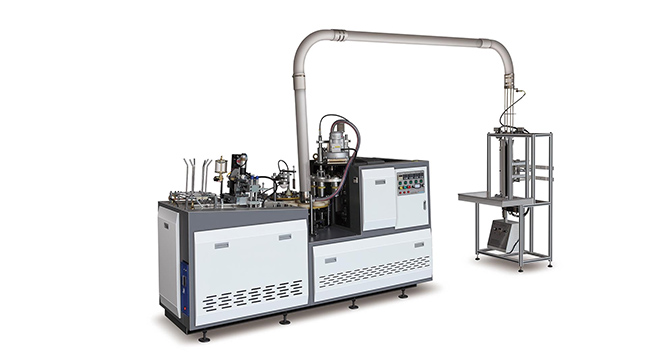

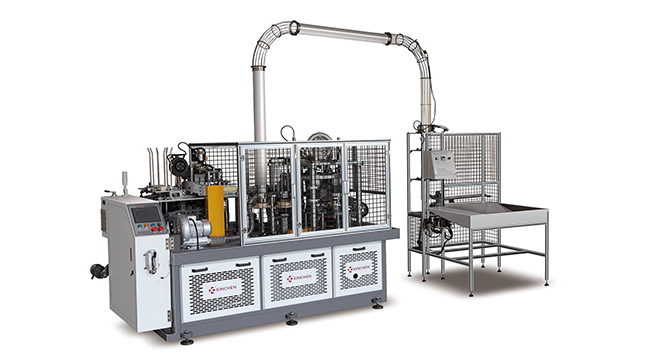

ZW-125 Intelligent Paper Bowl Machine adopts a desktop layout, with double-layer separation of transmission and forming. Double turntable structure, the middle turntable can realize the functions of cup mouth silicone oil and waste discharge.

|

Model |

ZW-125 |

|

Machine Weight |

3000KG |

|

Wooden case dimension |

2300*1300*1900mm (L*W*H) 1230*710*1950mm (Collect table) |

|

Rated power |

Three-phase,380V, 20KW |

|

Compressed air |

0.6-0.8MPa,0.4m³/min |

|

Capacity |

80-100pcs/min |

|

Paper materials |

Single PE/double PE |

|

Paper grammage |

150-300g/m² |

|

Product range |

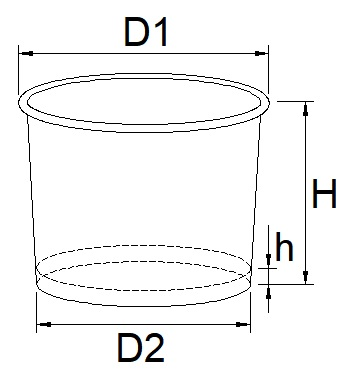

(D1)φ80-125mm (H)45-100mm |

|

|

(D2)φ70-98mm (h)4-10mm |