The paper bowl machine is used to make food containers such as salad bowls and soup bowls. It is a multi-station automatic forming equipment suitable for single and double PE coated paper. A set of paper bowl machines can handle tasks such as automatic paper feeding, preheating, sealing, oiling, bottom cutting, knurling, curling and collection. With photoelectric detection, fault alarm and counting functions, production can be easily monitored and managed. The produced paper bowls are beautiful and sturdy, and are ideal containers for salads, soups and fast food.

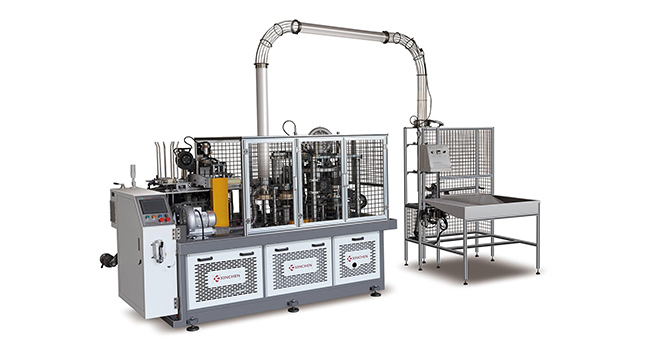

ZW-125 Intelligent Paper Bowl Machine adopts a desktop layout, with double-layer separation of transmission and forming. Double turntable structure, the middle turntable can realize the functions of cup mouth silicone oil and waste discharge.

|

Capacity |

80-100pcs/min |

|

Paper materials |

Single PE/double PE |

|

Paper grammage |

150-300g/m² |

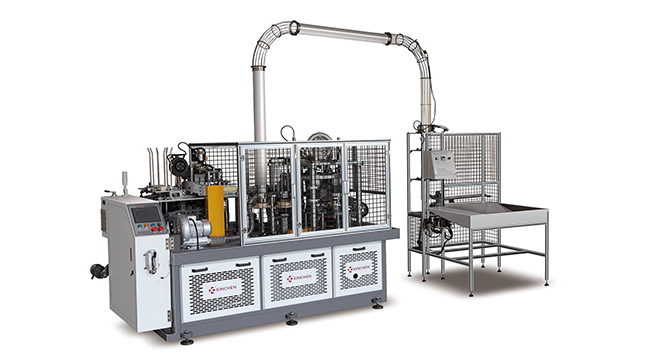

XC-B90 Middle Speed Paper Bowl Machine adopts PLC and touch screen control, servo feeding and photoelectric detection. Ideal for the production of salad bowls, noodle bowls and packaging bowls.

|

Capacity |

60-80pcs/min |

|

Paper materials |

Single PE/double PE |

|

Paper grammage |

150-350g/m² |

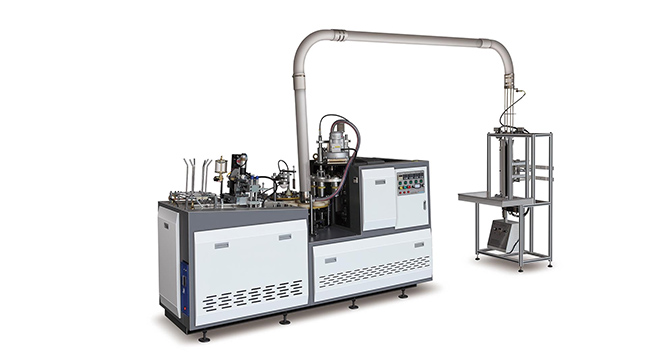

XC-B70 paper bowl machine, use intermittent cam, with automatic paper sending, sealing, oil, bottom punching, it’s suitable for large capacity Large-diameter bowl-shaped container ideal production equipment.

|

Production speed |

75-85pcs/min |

|

Electrical requirement |

7.5KW 380V 50Hz |

|

Weight |

1600KG |

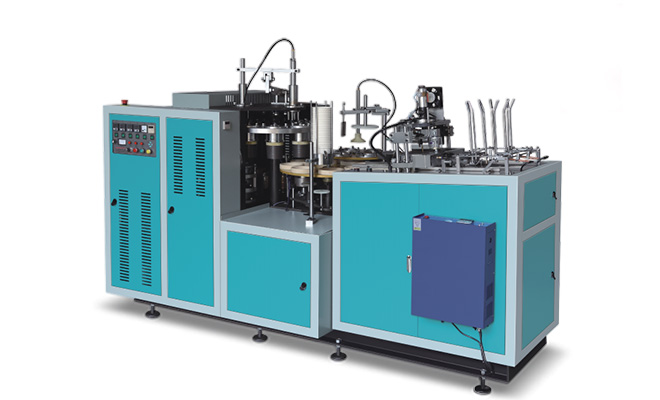

XC-B80 vertical single-coated or double-coated film paper bowl machine uses 150 type dividing box, it is the ideal production equipment for large capacity large diameter bowl container such as soup bowl, instant noodle bowl.

|

Capacity |

45-55pcs/min |

|

Rated power |

7/11KW 380V 50Hz |

|

Machine weight |

2000 KG |