In today's fast-paced food service and packaging industry, paper bowls are an important part of disposable tableware, and the choice of their production equipment—the paper bowl machine—is crucial. The right paper bowl machine can not only improve production efficiency and reduce costs but also ensure product quality and meet market demands.

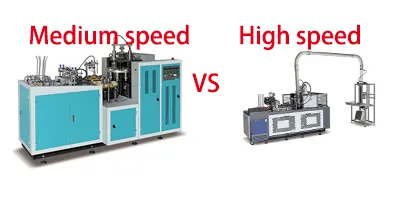

Ⅰ.production speed

When purchasing a paper bowl machine, the following parameters should be focused on: First is the production speed, which is directly related to production capacity.

Generally, high-speed paper bowl machines can produce over 100 pieces per minute, medium-speed machines around 60-100 pieces, and low-speed machines less than 60 pieces. Enterprises should choose reasonably based on their own order volume and production scale.

Ⅱ. produce a variety of sizes

Next is the compatibility of paper bowl specifications. A good paper bowl machine should be able to produce a variety of sizes, such as common sizes like 360ml, 450ml, and 650ml, to meet different customer needs.

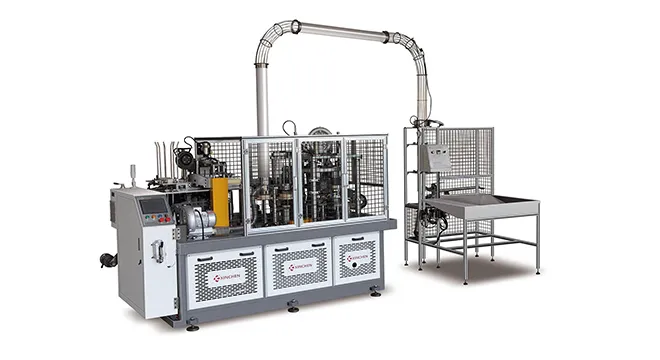

Furthermore, the stability and reliability of the equipment are indispensable. The quality of the transmission structure and electrical control system affects the long-term operation effect. For example, paper bowl machines that use precision gear transmission and advanced PLC control generally have higher stability.

Ⅲ.the degree of automation

In addition, the degree of automation is also key. Functions such as automatic paper feeding, forming, and bottom sealing can reduce manual intervention and improve production efficiency and product consistency.

Finally, energy consumption and maintenance costs are also worth considering. Energy-saving paper bowl machines can reduce operating costs, and equipment with simple structures and easy maintenance can reduce downtime due to failures.

Nov 10,2024

Nov 10,2024