In the vibrant panorama of paper bowl production, disposablePaper bowl machines have carved a distinct niche for themselves, diverging significantly from their counterparts in several crucial dimensions.

1. Ingenious Design and Structural Sophistication

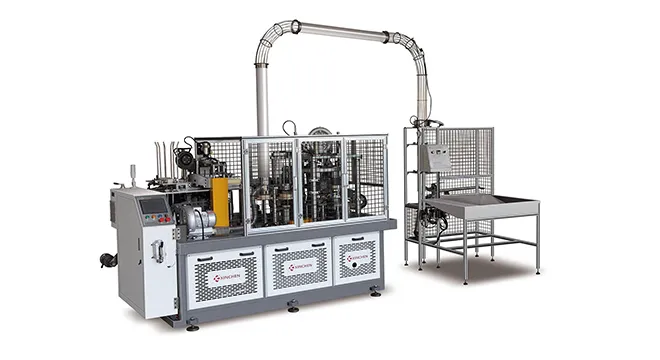

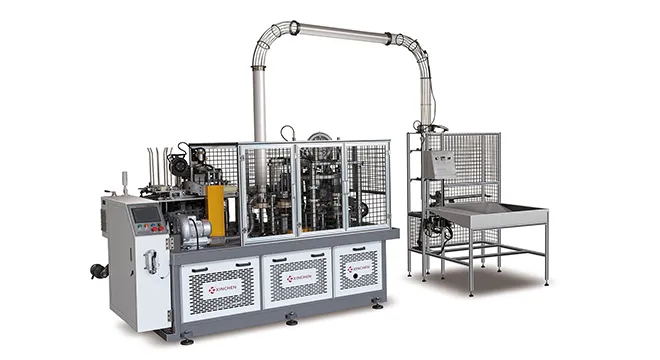

♦The architecture of disposablePaper bowl machines is a testament to innovation. Take the XC-B70 model, for example. Its inclined main-frame is a masterstroke of engineering. This carefully calibrated incline serves as a catalyst for seamless bowl collection. As the freshly formed bowls emerge from the production line, they gracefully slide into the plastic holes with an extraordinary success rate nearing 99.99%. In stark contrast, traditional paper bowl machines typically feature a flat or less refined frame layout. Such designs often precipitate bowl jams or misalignments during collection, sowing the seeds of inefficiency and potential product damage.

♦The contour of the sealing head further accentuates the machine's singularity. The oblate design of the disposablePaper bowl machine's head confers a remarkable sealing prowess. When juxtaposed with the ubiquitous round heads adorning other machines, it wields the ability to administer uniform pressure with surgical precision. This precision enables it to snugly conform to the contours of the bowl rim, forging an airtight and impermeable seal. In the context of applications demanding leak-proof integrity, such as soup bowls or piping hot drink cups, this enhanced sealing proficiency emerges as a decisive advantage, firmly establishing the disposablePaper bowl machine as a paragon in its class.

2. Precision-driven Operational Dynamics

♦At the heart of the disposablePaper bowl machine's operational excellence lies the intermittent cam mechanism. This intricate component serves as the maestro orchestrating a symphony of precise manufacturing processes. From the deft feeding of paper to the meticulous sealing, from the judicious application of oil to the unerring bottom punching, each step unfolds in a choreographed sequence of unerring accuracy. In contrast, alternative paper bowl machines often rely on less refined drive systems. These systems may falter in delivering consistent paper feed lengths, resulting in erratic sealing or haphazardly punched bottoms. Such inconsistencies invariably undermine the structural and functional integrity of the paper bowls.

♦The employment of double layer suckers for cup fan suction represents another hallmark of the disposablePaper bowl machine's superiority. These state-of-the-art suckers unleash a formidable and unwavering suction force. In comparison to the often lackluster single-layer or less efficient suction modalities in competing machines, they ensure an unyielding grip on the paper cups throughout the manufacturing odyssey. This tenacious hold not only safeguards against displacement but also significantly extends the operational lifespan of the suckers. By curtailing the frequency of sucker replacements and the attendant production downtimes, the disposablePaper bowl machine turbocharges overall productivity, emerging as an unrivaled workhorse in the paper bowl manufacturing arena.

3. Unwavering Performance and Efficiency Eminence

♦In the realm of performance metrics, disposablePaper bowl machines reign supreme. The XC-B70 model, for instance, effortlessly attains a production cadence of 75 - 85 pcs/min while deftly optimizing power consumption. Its strategic utilization of a 100 type speed reducer, supplanting the 80 type prevalent in some other machines, unlocks a new echelon of transmission efficiency. This enhancement ensures that a greater proportion of the input power is channeled with unerring precision into driving the manufacturing processes, slashing energy wastage to the bare minimum. The augmented parallelism, hypersensitivity, and pinpoint precision of the speed reducer synergize to orchestrate a seamless and error-free operational ballet. In contrast, many other paper bowl machines find themselves ensnared in a quagmire of compromise, sacrificing either speed or power efficiency in a fruitless attempt to strike a balance.

♦The disposablePaper bowl machine's versatility in material handling is equally remarkable. It exhibits a remarkable aptitude for processing a broad spectrum of paper grammages. Ranging from 150 - 250 g/m² single PE to 150 - 380 g/m² single PE/double PE with ultrasonic enhancements, it effortlessly adapts to diverse material specifications. This adaptability empowers manufacturers to respond nimbly to a kaleidoscope of customer demands and product idiosyncrasies. In contrast, certain other machines labor under the constraints of limited material compatibility, confining their product offerings and impeding their ability to cater to the multifaceted exigencies of the market.

In summation, the disposablePaper bowl machine, with its avant-garde design, precision-engineered operational mechanisms, and unassailable performance benchmarks, emerges as a luminous beacon in the paper bowl manufacturing constellation. It outshines its competitors across a plethora of parameters, heralding a new era of excellence in the industry.

Dec 11,2024

Dec 11,2024