In the current market environment, the choice of a paper cup machine is of great significance for enterprises engaged in the paper cup manufacturing industry. Here are the top five considerations when selecting a paper cup machine.

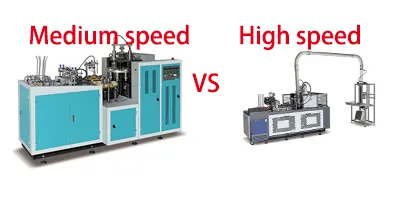

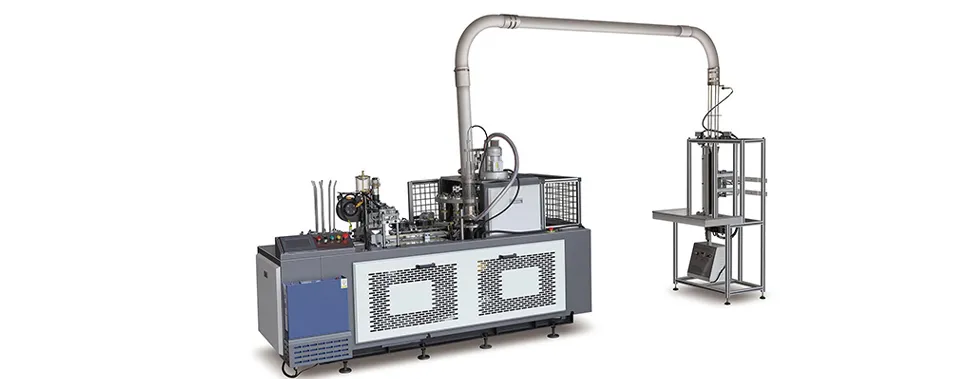

1. Production Capacity and Efficiency

The production capacity of a paper cup machine is a crucial factor. High-speed paper cup machines can produce a large number of paper cups per hour, which is essential for meeting large orders. For example, some advanced models can manufacture thousands of cups within an hour. This not only improves production efficiency but also shortens the delivery cycle, enhancing the enterprise's competitiveness in the market. Consider the production volume requirements of your enterprise and choose a machine that can meet or exceed those needs.

2. Cup Quality and Precision

The quality and precision of the paper cups produced directly affect the brand image and user experience. A good paper cup machine should be able to precisely control the size, shape, and thickness of the cups. The cups should have a uniform appearance, smooth edges, and reliable sealing. Machines with advanced forming and cutting technologies can ensure that each cup is of high quality. Check the sample cups produced by the machine and evaluate their quality and consistency before making a decision.

3. Material Compatibility

Paper cup machines need to be compatible with different types of paper materials. Different paper materials have different properties, such as thickness, strength, and water resistance. The machine should be able to handle a variety of paper weights and coatings. For instance, it should work well with both coated and uncoated papers, as well as papers with different grammages. This flexibility in material compatibility allows manufacturers to produce a wide range of paper cups to meet diverse market demands.

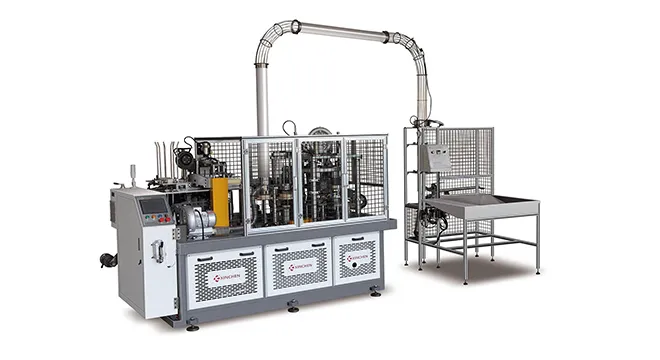

4. Automation and Ease of Operation

Automation is a key trend in modern manufacturing. A paper cup machine with a high degree of automation can reduce labor costs and human errors. It should have features like automatic paper feeding, cup forming, and stacking. The control system should be user-friendly, allowing operators to easily set parameters and monitor the production process. Look for machines with intuitive interfaces and reliable automation functions to ensure smooth and efficient operation.

5. After-Sales Service and Support

After-sales service is often overlooked but is extremely important. A reliable supplier should provide good after-sales service, including installation, training, and maintenance. In case of any technical issues or breakdowns, prompt technical support should be available. Check the reputation of the supplier and their after-sales service network. A good after-sales service can ensure the long-term stable operation of the paper cup machine and minimize production disruptions.

When selecting a paper cup machine, carefully consider these five aspects to make an informed and optimal choice that suits your enterprise's specific needs and helps you succeed in the competitive paper cup manufacturing market.

Dec 10,2024

Dec 10,2024