In recent years, with the continuous development of the paper cup packaging industry, intelligent double wall paper cup sleeve machines have gained significant popularity. These machines come in a variety of styles, each designed to meet different production needs and market demands.

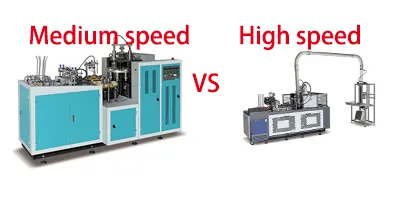

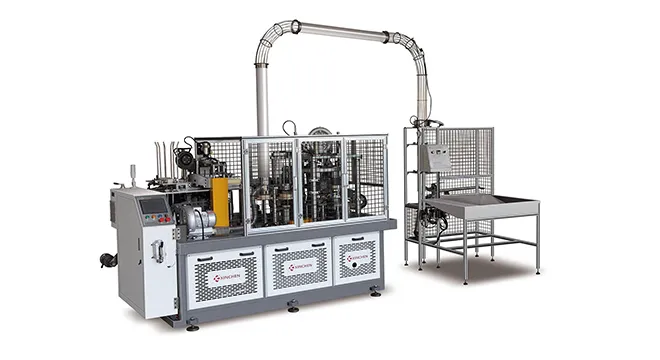

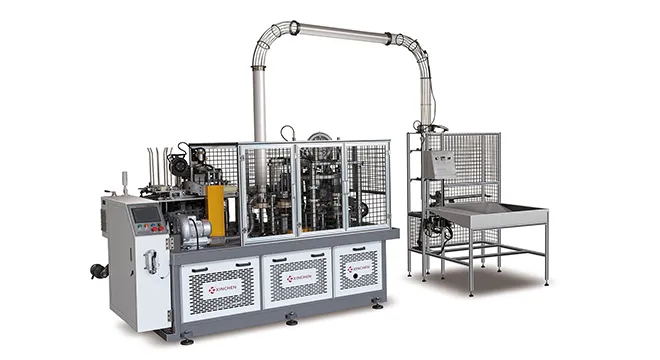

1. High-Speed Automatic Style

One of the prominent styles is the high-speed automatic Intelligent Double Wall Paper Cup Sleeve Machine.

How does it work?

This type is engineered to maximize production efficiency. It is equipped with advanced servo motor systems that ensure precise control over the paper feeding, cutting, and gluing processes. For example, some models can produce up to 200 or more cup sleeves per minute. The paper is first loaded onto a large-capacity paper roll holder. Then, the servo motors precisely control the speed and amount of paper fed into the machine. The cutting mechanism, which is also controlled by the servo system, accurately cuts the paper into the required lengths for the cup sleeves. The gluing process is automated and precisely regulated to ensure proper adhesion.

What are its advantages?

It is ideal for large-scale paper cup manufacturing enterprises that have a high volume of orders to fulfill. The high-speed operation is achieved through optimized mechanical designs and intelligent control algorithms. The machine can automatically adjust parameters such as the speed of paper conveyance and the amount of glue applied based on real-time production data. This style of machine usually has a large-capacity paper roll holder, reducing the frequency of paper roll replacement and further enhancing continuous production capabilities.

2. Compact and Versatile Style

Another style available is the compact and versatile Intelligent Double Wall Paper Cup Sleeve Machine.

What makes it special?

As the name suggests, it is characterized by its relatively small footprint, making it suitable for factories or workshops with limited space. Despite its compact size, it does not compromise on functionality. It can handle a wide range of paper materials, including different thicknesses and qualities of paper. This versatility allows manufacturers to produce cup sleeves with various textures and appearances. For instance, it can work well with both recycled paper and high-quality specialty papers.

How is it operated?

The machine is often equipped with user-friendly interfaces that enable operators to easily switch between different production modes and settings. Operators can input the desired parameters such as the size of the cup sleeve, the type of paper, and the production quantity. The machine then automatically adjusts its internal mechanisms to start the production process.

3. Multifunctional Integrated Style

The multifunctional integrated Intelligent Double Wall Paper Cup Sleeve Machine is a more advanced and comprehensive option.

What additional functions does it have?

In addition to the basic functions of producing double wall paper cup sleeves, it incorporates additional features. For example, some models can also perform operations such as embossing or printing directly on the cup sleeves during the manufacturing process. This means that manufacturers can create cup sleeves with unique patterns, logos, or promotional messages in a single production step, saving time and resources.

How does the integration work?

The machine is equipped with high-precision printing and embossing mechanisms that can achieve detailed and clear designs. It also has advanced quality control systems that can detect and correct any defects or errors in the production process in real-time. The printing and embossing mechanisms are synchronized with the main production process, so that when the cup sleeve is being formed, the printing or embossing is done simultaneously.

4. Eco-Friendly Style

With the increasing emphasis on environmental protection, the eco-friendly Intelligent Double Wall Paper Cup Sleeve Machine has emerged.With the increasing emphasis on environmental protection, the eco-friendly Intelligent Double Wall Paper Cup Sleeve Machine has emerged.

How is it environmentally friendly?

These machines are designed to minimize environmental impact throughout the production process. They are optimized to work with sustainable paper materials, such as papers sourced from responsibly managed forests or recycled paper with a high post-consumer waste content. The machines also employ energy-efficient technologies, such as energy recovery systems during the heating and drying processes. Some models even use biodegradable glues and inks, ensuring that the entire cup sleeve production is as environmentally friendly as possible.

What are the benefits for businesses?

This style of machine caters to the growing market segment of consumers and businesses that prioritize sustainability and are willing to invest in greener production methods. By using such a machine, businesses can enhance their brand image as an environmentally conscious company, which may attract more customers and partners.

Frequently Asked Questions

Q: Can these machines be customized to fit specific cup sizes?

A: Yes, most of the intelligent double wall paper cup sleeve machines can be adjusted to produce sleeves for different cup sizes. The operators can input the specific dimensions into the machine's control system, and the machine will adapt its forming and cutting processes accordingly.

Q: How difficult is it to maintain these machines?

A: The maintenance level varies depending on the style of the machine. Generally, regular cleaning of the paper feeding and gluing parts is required. High-speed automatic machines may require more technical expertise for maintenance due to their complex servo systems, while compact and versatile machines are usually easier to maintain. Manufacturers usually provide maintenance manuals and technical support to assist users.

Q: What is the typical lifespan of these machines?

A: The lifespan of an intelligent double wall paper cup sleeve machine depends on factors such as usage frequency, maintenance quality, and the quality of components. With proper maintenance and regular use, a machine can last for 5 to 10 years or even longer.

Summary

The market offers a diverse range of Intelligent Double Wall Paper Cup Sleeve Machines. The high-speed automatic style is for large-scale production, the compact and versatile style suits limited space and diverse material needs, the multifunctional integrated style provides added value with extra features, and the eco-friendly style meets the demands of sustainability. Manufacturers can choose the style that best suits their specific requirements and contribute to the efficient and sustainable production of double wall paper cup sleeves. Whether it is high-speed production, compactness, multifunctionality, or environmental friendliness, there is a machine option available to meet different production and market demands.

Dec 11,2024

Dec 11,2024