In an era where convenience meets environmental responsibility, the demand for disposable yet eco-friendly packaging solutions has skyrocketed. At the heart of this revolution lies the Paper Cup Machine—a cornerstone of modern manufacturing for producing disposable cups used in cafes, offices, and events. This article explores the cutting-edge technology behind High Speed Paper Cup Machines, their diverse applications, and critical factors for selecting a reliable Paper Cup Making Machine supplier.

1. The Engineering Behind Modern Paper Cup Machines

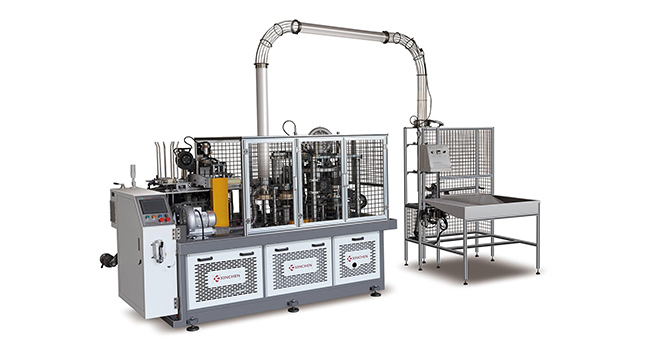

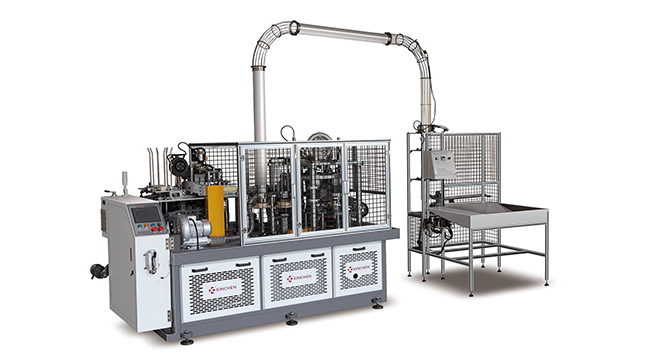

The Paper Cup Forming Machine has evolved from rudimentary manual devices to fully automated systems capable of producing thousands of cups per hour. Modern machines integrate precision engineering with advanced materials to ensure consistency and durability. Key innovations include:

-

Ultrasonic Seal Paper Cup Machine: Utilizes high-frequency vibrations to create airtight, leak-proof seals without adhesives, ideal for hot and cold beverages.

-

PE Coating Paper Cup Machine: Applies a thin layer of polyethylene (PE) to paperboard, enhancing water resistance while maintaining recyclability.

For high-volume production, the High Speed Paper Cup Machine stands out, boasting outputs of 80–150 cups per minute. These systems are equipped with servo-driven mechanisms, reducing material waste and energy consumption.

2. Key Features of a High-Quality Paper Cup Machine

When investing in a High Quality Paper Cup Machine, prioritize the following attributes:

-

Speed and Efficiency: Automated feeding, forming, and ejection systems minimize downtime.

-

Versatility: Adjustable dies and tooling accommodate various cup sizes (e.g., 4 oz to 24 oz) and shapes.

-

Eco-Friendly Design: Machines compatible with biodegradable or PE-coated paper align with sustainability goals.

-

Durability: Stainless steel components and robust frames ensure longevity in demanding environments.

The Disposable Paper Glass Making Machine exemplifies versatility, producing not only cups but also customizable containers for ice cream, soups, and desserts.

3. Applications Across Industries

From bustling coffee chains to corporate cafeterias, Paper Cup Making Machines serve diverse sectors:

-

Food & Beverage: Producing cups for coffee, tea, soft drinks, and takeaway meals.

-

Healthcare: Manufacturing sterile disposable cups for medical facilities.

-

Events & Hospitality: Delivering branded cups for conferences, festivals, and hotels.

The Ultrasonic Seal Paper Cup Machine is particularly valued in the beverage industry for its ability to securely seal lids, preventing spills during transit.

4. Choosing the Right Paper Cup Machine Supplier

Partnering with a reputable Paper Cup Machine manufacturer is critical to maximizing ROI. Consider these factors:

-

Technical Support: Suppliers should offer training, maintenance guides, and troubleshooting assistance.

-

Customization: Ability to integrate features like edge curling, bottom pressing, or custom printing.

-

Compliance: Machines adhering to FDA or EU standards for food-grade materials.

Leading manufacturers often provide PE Coating Paper Cup Machines with adjustable coating thickness, catering to specific moisture resistance requirements.

5. Cost Efficiency and Sustainability

While the initial investment in a High Quality Paper Cup Machine may seem substantial, long-term savings are achieved through reduced labor costs, minimal material waste, and energy-efficient operations. For businesses prioritizing eco-friendliness, opting for PE Coating Paper Cup Machines that use recyclable materials aligns with global sustainability trends.

Mid-sized enterprises often favor semi-automatic models for flexibility, while large-scale producers rely on High Speed Paper Cup Machines to meet bulk orders.

Conclusion

The Paper Cup Machine is more than a manufacturing tool—it’s a gateway to meeting consumer demands for convenience, hygiene, and environmental stewardship. Whether you require a Disposable Paper Glass Making Machine for specialty containers or a Ultrasonic Seal Paper Cup Machine for premium beverage packaging, investing in advanced technology ensures competitiveness in a dynamic market.

By selecting a trusted Paper Cup Making Machine supplier and leveraging innovations like PE coating and ultrasonic sealing, businesses can deliver high-performance, sustainable solutions that resonate with eco-conscious customers.

Mar 13,2025

Mar 13,2025