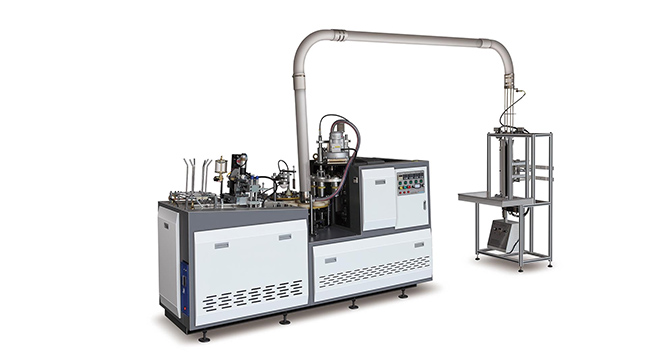

WT-116 Double wall Paper Cup Sleeve Machine adopts open-type, intermittent division design, gear drive, longitudinal axis design, so they can reasonably distribute each part function. The whole machine adopts spray lubrication.

|

WT-116 |

|

|

Weight: |

2400 kg |

|

Machine encasement dimensions: |

2400 * 1450 * 1900mm |

|

Connecting power: |

380V, 5KW |

|

Compressed air: |

0.6-0.8MPa, 0.4m³/min |

|

Production capacity: |

Hollow/appressed: 80-120pcs/min; Corrugated: 80-100pcs/min; |

|

Paper types: |

White board/ Grey board |

|

Paper thickness: |

0.2825-0.4075mm |

|

Product range: |

(D1) ф70-95mm (H) 60-130mm (D2) ф50-75mm (h) 0-12mm |

|

Long term magazine: |

○ |

|

Control panel: |

7 inches |